Fast, Accurate, Affordable Petrophysical Analysis

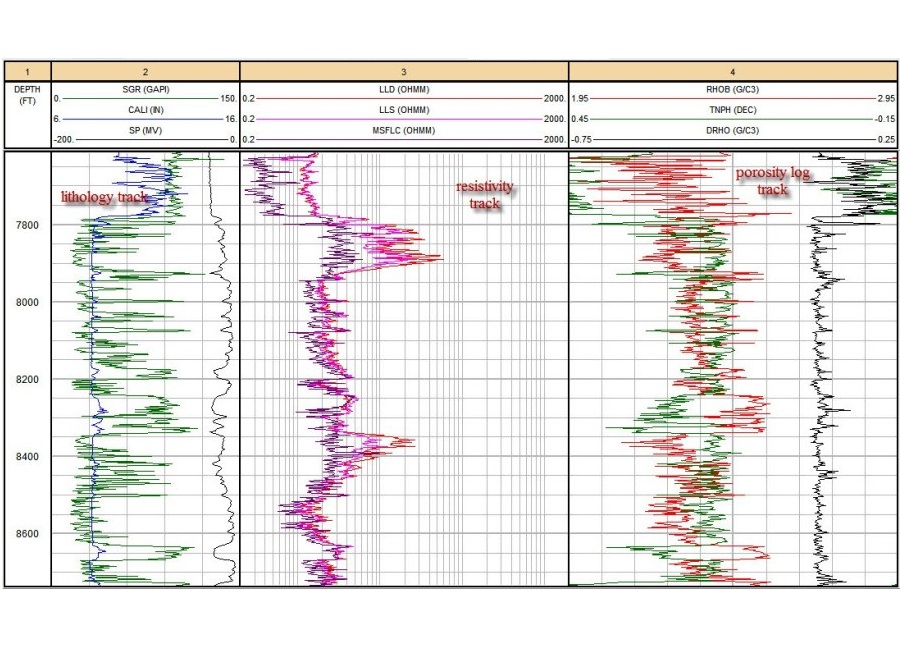

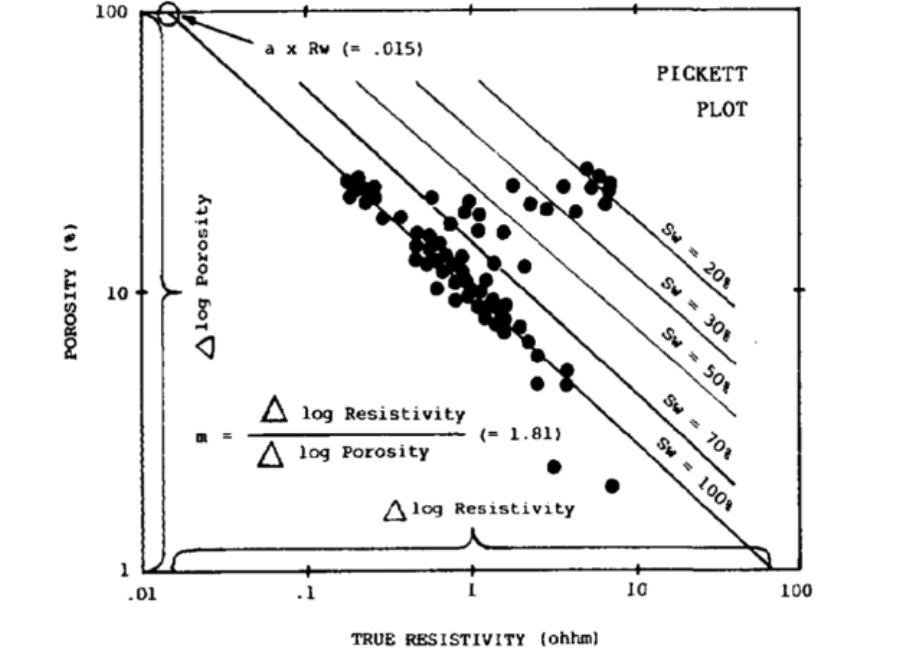

SuperLog™ is more than software: it is a complete solution for Petrophysicists, Geophysicists, Geologists, and Reservoir Engineers who need results with both speed and precision.

With its intuitive interface and research-driven modules, SuperLog™ transforms complex petrophysical analysis into a streamlined workflow, delivering deeper insights without slowing you down.

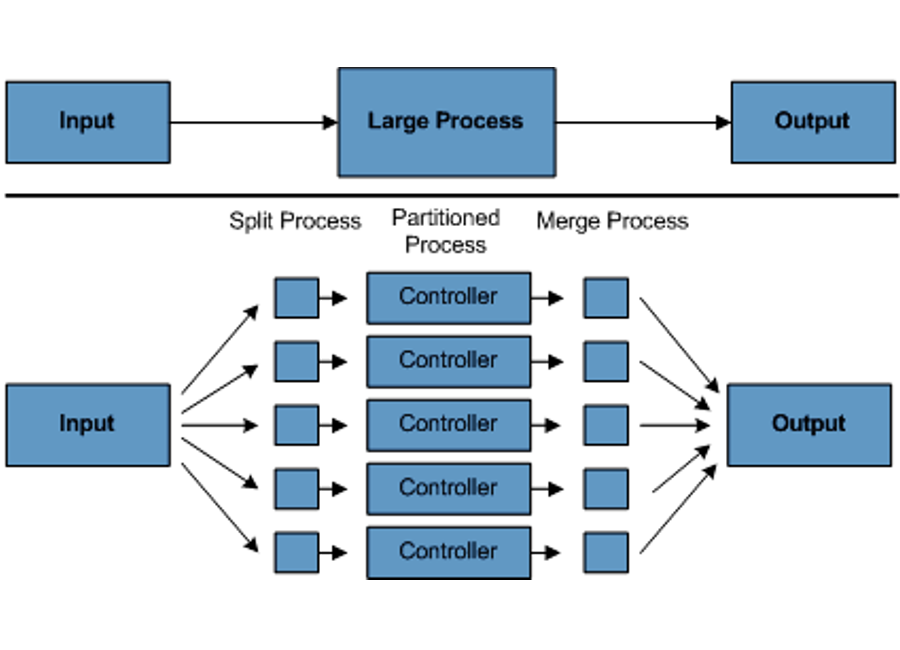

From single-well studies to large-scale, multi-well projects, SuperLog™ combines technical excellence with a competitive price, empowering your team to focus on interpretation, not the tools.

Download Free Trial